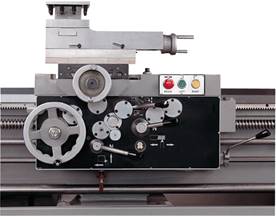

HEAVY DUTY LATHE (15HP Main motor; spindle bore105mm 4-1/8inch)

Model: 2480, 24120, 24160, 3080, 30120, 30160

FEATURES:

˙4-1/8in (105mm) Spindle bore; D1-11 camlock spindle nose; 3-bearing spindle support.

˙18 Spindle speeds, 10-1200 rpm, with electro-magnetic brake.

˙Electro-magnetic clutch mounted in Headstock, for spindle speed changed without stopping motor.

˙Automatic forced lubrication in headstock is moved by a direct motor drive lubrication gear pump, and oil tank is equipped in the leg of machine to minimize the cooling of oil.

˙Heavy duty geared head; hardened and ground gears.

˙15HP Main spindle motor.

˙Quick-change universal gearbox for inch, metric, DP, MP, threading, and multiple thread, all function without any change gears.

˙Four-way rapid carriage movement.

˙Automatic lubrication in saddle and apron assembly.

˙Adjustable overload clutch in apron to ensure proper cutting load.

˙2 speeds tailstock barrel.

˙19in. (485mm) wide bed ways, induction hardened and ground.

|

|

|

|

|

|

|

|

|

|

1. The clutch headstock is suitable for big and repeatability processing parts.

2. The spindle bore is 105mm(4"), uses Timken roller bearings, 3-point support, make the ability of heavy-cutting stronger.

3. The spindle bore uses Electro Magnetic brake. Speed up the reaction time of brake, cut the inertia by mechanical brake.

4. We have Automatic lubrication system & Tank on the headstock and gearbox. The pump with lubricating oil tank can strengthen the lubrication, lower the temperature and increase the heat dissipation.

5. The Univeral gear box with DP & MP thread need to change the exchange gear.

6. A wide ragne of threading can be easily change by the handle

7. The multiple theading can cutting directly by the handle switching.

8. 4 way Rapid Traverse system can protect mechanism if collision happened.

9. The steering rod of auto feed make operatoer easy to use.

10. The Overload safety protection inside the apron will protect safety of operators. The cluth will automatically cut off when wrongly processing or block.

11. The Automatic lubrication system & Tank in the apron and cross slide can automatically lubricate when operating.

12. 2 Speeds feed Talistock makes easily operation.

13. The bed rails 485 mm(19"), 65˚ makes more stability of heavy cutting.

14. Y-△ has small start-up current, can ease the burden of equipment and motor instant start.

BRIEF SPECIFICATION |

||||||

|

MODEL |

2480 |

24120 |

24160 |

3080 |

30120 |

30160 |

|

NOMINAL SIZE |

||||||

|

Swing over Bed |

610mm 24in |

760mm 30in |

||||

|

Swing over Cross Slide |

350mm 13-3/4in |

500mm 19-3/4in |

||||

|

Height of Center |

305mm 12in |

380mm 15in |

||||

|

Distance Between Centers |

2033mm 80in |

3050mm 120in |

4050mm 160in |

2033mm 80in |

3050mm 120in |

4050mm 160in |

|

BED |

||||||

|

Width of Bedways |

485mm 19in |

|||||

|

Total Length of Bed |

3320mm130in |

4380mm 172in |

5470mm 215in |

3320mm 130in |

4380mm 172in |

5470mm 215in |

|

Swing over Gap |

820mm 32-1/4in |

970mm 38-1/4in |

||||

|

Length of gap |

515mm 20-1/4in |

|||||

|

Width in front of face plate |

340mm 13-3/8in |

|||||

|

SPINDLE |

||||||

|

Spindle nose mounting |

D1-11 CAMLOCK |

|||||

|

Spindle bore |

105mm 4-1/8in |

|||||

|

Taper of spindle bore |

M.T.#5 (with center sleeve) |

|||||

|

Number of spindle speeds |

18 steps (Forwarded & Reversed by magnetic clutch control) |

|||||

|

Range of spindle speeds |

10-1200 R.P.M. (with Magnetic brake) |

|||||

|

TOOL SLIDE |

||||||

|

Total travel of cross slide |

375mm 14-3/4in |

|||||

|

Total travel of top slide |

225mm 9in |

|||||

|

Max. size cutting tool |

32mm 1-1/8in |

|||||

|

TAIL STOCK |

||||||

|

Total travel of tailstock barrel |

195mm 6-5/8in |

|||||

|

Taper in tailstock barrel |

M.T.#5 |

|||||

|

Diameter of barrel |

80mm 3-1/8in |

|||||

|

THREADS |

||||||

|

Lead screw diameter & pitch |

Dia. 38mm Pitch 12mm 2 T.P.I. |

|||||

|

Inch threads |

1/4-84 TPI (60) |

|||||

|

Metric pitches |

0.2-112mm(60) |

|||||

|

Diametral pitches |

1-240 D.P.(55) |

|||||

|

Module pitches |

0.05-28 M.P.(55) |

|||||

|

FEEDS |

||||||

|

Feed rod diameter |

38mm 1-1/2in |

|||||

|

Range of longitudinal feeds |

0.040-5.000mm/rev. 0.0015-0.20 in/rev.(40) |

|||||

|

Range of cross feeds |

0.015-4.000mm/rev. 0.0006-0.15 in/rev. |

|||||

|

MOTOR |

||||||

|

Main spindle motor |

15HP 11kw |

|||||

|

Coolant pump motor |

1/8HP 0.1kw |

|||||

|

WEIGHT |

||||||

|

Machine net weight |

3500kgs |

4000kgs |

4500kgs |

3800kgs |

4300kgs |

4800kgs |

We reverse the right to modify and improve our products.